Kaksoisreunainen hiilikiveliittymä polttoaineen varastointitankki

1. Kaksoisreunaisten hiilikiveliittymien polttoaineen varastointitankkien rakenne ja suunnittelu

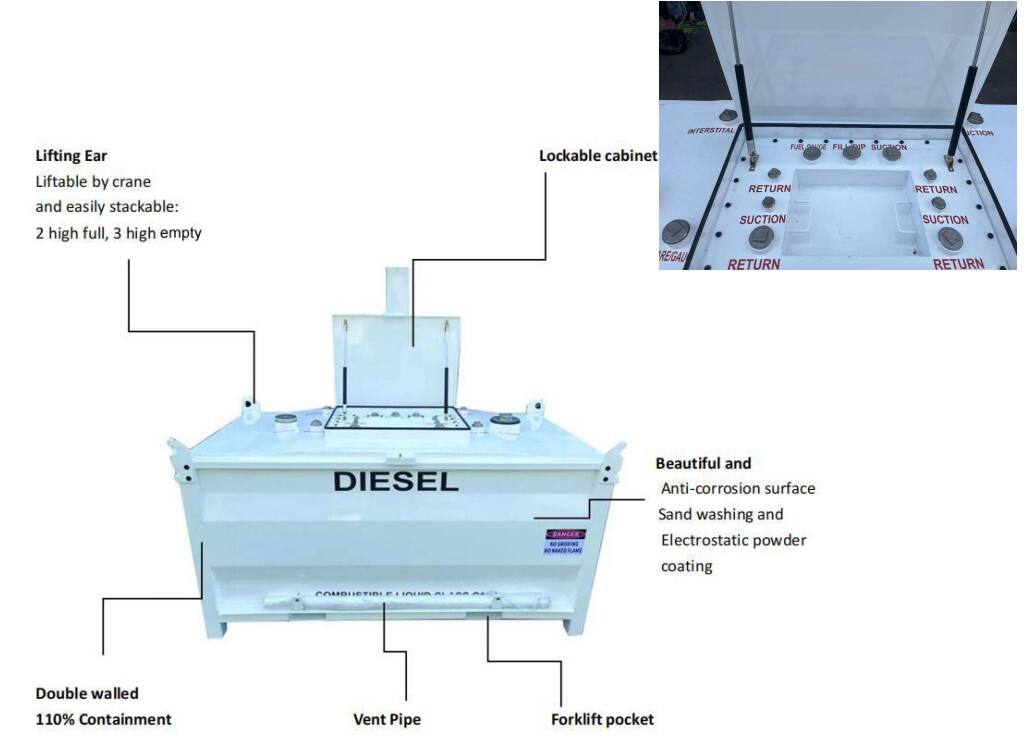

Kaksoisreunainen hiilivetykyninen polttoainevarastotanko koostuu sisäisestä tankosta ja ulkoisesta tankosta. Sisäinen tankki on ensisijainen polttoaineen säilytyspaikka ja se on yleensä tehty hiilivetyksestä, joka tarjoaa vankkaan esteen polttoaineen vastustukseen. Ulkoinen tankki toimii toissijaisena sisäisyyden säilyttämiseksi. Sisäisen ja ulkoisen tankon välinen tila, jota kutsutaan väliavaruudeksi, on tärkeä turvallisuusominaisuus.

Nämä tankojen seinät suunnitellaan tietyillä paksuksilla riippuen tankin kapasiteetista, tallennettavan polttoaineen tyypistä ja vaadituista turvallisuusstandardeista. Esimerkiksi erittäin syttyvien polttoaineiden, kuten benzinan, varastointiin seinät täytyy olla pakettuja riittävästi kestääkseen potentiaalisia iskuja ja painemuutoksia. Tankot ovat usein sylinterimuotoisia, koska tämä geometria jakaa stressin tasaisesti ja on rakenteellisesti tehokas.

2. edut

Lisätty turvallisuus:

Kaksoisreikäinen rakennus tarjoaa ylimääräisen suojakerroksen polttoainevuotoja vastaan. Jos sisäinen tankki kehittää vuodatuksen, uloinen tankki voi sisältää polttoaineen, estämällä sen saastuttamasta ympäristöönsä. Tämä on ratkaisevan tärkeää sekä ympäristön suojelemiseksi että tulipalosta turvallisuuden varmistamiseksi. Esimerkiksi polttoainevarastossa lähellä vesistöä tai asutettua aluetta kaksoisreikäinen tankki vähentää huomattavasti riskiä siitä, että polttoaine leviää maahan ja pääsee jokiin tai virtsaantoihin.

Välilyönti tila voidaan valvoa merkkejä polttoainevuodatuksista. Anturit voidaan asentaa tähän tilaan polttoaineen läsnäolon havaitsemiseksi. Jos polttoainetta havaitaan, se käynnistää hälytyksen, mikä mahdollistaa välitöntä toimintaa ja korjausta ennen kuin suuri vuoto tapahtuu.

Noudattaminen säännöistä: Monet ympäristö- ja turvallisuussäännökset edellyttävät kaksinpuiden varastointitankkujen käyttöä, erityisesti suurten määrien polttoaineiden varastoinnissa. Nämä tankit auttavat yrityksiä ja teollisuutta täyttämään tiukat säädetyt vaatimukset satumien estosta ja sisällytyksestä. Esimerkiksi öljy-alalla, jossa suuria määriä polttoainetta varastoidaan ja kuljetetaan, kaksinpuiden tankkujen käyttö on standardikäytäntö noudattaakseen paikallisia ja kansallisia ympäristönsuojelulainsäädäntöä.

3. Haitat

Korkeampi hinta: Kaksinpuiden hiilivarojen polttoainevarastointitankkujen rakentaminen on monimutkaisempaa ja vaatii enemmän materiaaleja kuin yksinpuiden tankkujen. Materiaalien, valmistuksen ja asennuksen kustannukset ovat merkittävästi korkeammat. Tämä voi olla este pienille operaatioille tai niille, joilla on budjettirajoitteita.

Avaruusvaatimukset: Kaksiosoinen - seinätankit vievät enemmän tilaa lisäseinän ja väliavaruuden takia. Tämä voi olla rajoitus laitteistoissa, joissa tila on arvokasta. Esimerkiksi tiivistyneessä kaupunkialueen polttoainepaikassa kaksiosaisen tankin asettaminen saattaa vaatia enemmän maanalaisalueita, mikä voi olla haaste.

4. Huolto ja tarkastus

Säännöllinen tarkastus kaksiosoisista tankkeista on välttämätöntä. Ulkoseinää tulisi tarkistaa korroosion, murskauksien tai muiden fyysisen vahingon merkkejä. Välilaitos täytyy seurata polttoaineen tunnustamiseksi, mikä voi osoittaa sisäisen tankin vammoittautumisesta. Huoltomenettelyt voivat sisältää ulkopinnan maalia korroosion estämiseksi, siglujen ja liitoskohtien kokonaisuuden tarkastamista sekä väliavaruuden aineistojen testausta.

Routinamaisia visuaalisia tarkastuksia lisäksi voidaan käyttää kehittyneempiä tarkastusmenetelmiä, kuten ultrallisen testausta arvioidaksesi tankin seinän paksuutta ja havaitaksesi mahdolliset piilotetut vikat tai metallin ohenehtumisen. Tämä auttaa ennustamaan tankin jäljellä olevan käyttökelpoisuusaikansa ja varmistamaan sen turvallisen toiminnan jatkuvasti.

https://www.sumachine.com/

Suositellut tuotteet

Kuumat uutiset

-

Kaksinkertainen seinämökin kätevä diesel- tai benzinakuutionkattila pomppikauppa Mauritiusille

2024-11-11

-

Kaksiosainen Siirrettävä Polttoaineen Siirtotanko Neliömuotoinen Tankki Lähetetään Espanjaan

2024-11-07

-

Lähetys kuvioliikenteen polttoaineen säiliöstä pomppiin

2024-10-12

-

Hiileteräksi diesel polttoainetankki USAan

2024-11-14

-

Hiileteräksi kuutionmuotoinen tankki pomppineen

2024-11-13

-

Polttainenvirtauskuution tankki pysyvä kaksiosoinen dieselvarasto myytävänä Espanjaan

2024-11-06

-

251 Yhdysvaltain gallon 552 gallon polttoaineen kuutio siirtotankki myynti USA:han

2024-11-05

-

251-2000 gallon polttoaineen kuutio siirtotankki myynti Grenadalle

2024-11-01

-

552 gallon portable polttoaineen annostin tankki myynti USA:han

2024-10-30

-

Liukasta polttoainetankki pomppikauppa Espanja

2024-10-22

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

IS

IS

KA

KA

HT

HT

KK

KK

UZ

UZ