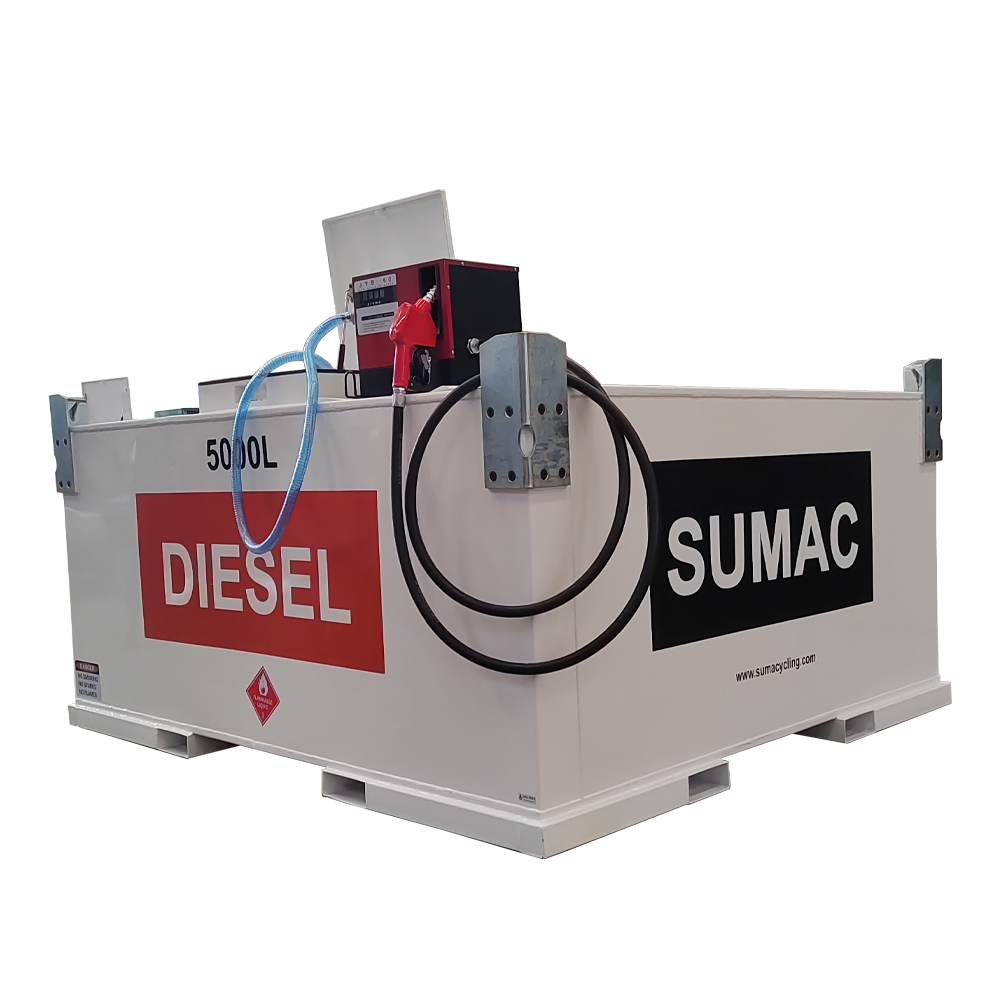

Carbon Steel Mobile Fuel Tank with Pump

A carbon steel mobile fuel tank with a pump is a device used for storing and dispensing fuel in a mobile or portable context. Here's a detailed description:

1. Carbon Steel Construction

Material Properties: Carbon steel is a popular choice due to its strength and durability. It can withstand the pressure exerted by the fuel inside the tank and is resistant to physical damage to some extent. For example, it can handle the bumps and vibrations that a mobile tank might experience during transportation.

Corrosion Resistance: However, carbon steel is prone to corrosion, especially when in contact with moisture and certain chemicals present in fuels. To mitigate this, the tank is usually coated with a corrosion - resistant paint or other protective coatings. For instance, a zinc - rich primer can be applied to provide a sacrificial layer that corrodes first, protecting the underlying steel.

2. Mobile Fuel Tank Features

Size and Capacity: Mobile fuel tanks come in various sizes. They can range from small tanks with a capacity of a few gallons (useful for small - scale equipment refueling like lawn mowers) to larger ones with capacities of several hundred gallons (used for refueling construction equipment or generators at job sites). The size is designed to balance the need for sufficient fuel storage and ease of transportation.

Portability: These tanks are equipped with features that make them mobile. They often have wheels (ranging from small caster wheels for light - duty tanks to heavy - duty pneumatic wheels for larger ones) and a tow hitch or handle for easy movement. Some may also be designed to fit on trailers, allowing them to be towed behind vehicles.

Safety Features: Mobile fuel tanks have several safety mechanisms. They are usually equipped with vents to allow for the release of pressure build - up due to temperature changes or fuel evaporation. The vents are designed to prevent the tank from exploding. Additionally, the tanks are often double - walled or have spill - containment features to prevent fuel leaks and spills.

3. The Pump

Pump Type: The pump attached to the fuel tank can be of different types. A common type is a hand - operated pump, which is simple and reliable. It allows for a controlled flow of fuel. For more heavy - duty applications, an electric pump may be used. Electric pumps can provide a higher flow rate, which is useful when refueling large equipment quickly.

Flow Rate and Precision: The flow rate of the pump is an important factor. It is measured in gallons per minute (GPM). A typical hand - pump might have a flow rate of 1 - 5 GPM, while an electric pump can have a flow rate ranging from 5 - 20 GPM or more, depending on its power. The pump also allows for precise dispensing of fuel, which is crucial for accurate record - keeping and preventing over - filling.

Compatibility: The pump needs to be compatible with the type of fuel being stored in the tank. For example, a pump used for gasoline must be designed to handle the volatility and flammability of gasoline, while a pump for diesel fuel can have different specifications.

These mobile fuel tanks with pumps are used in a variety of industries such as construction, agriculture, and transportation for on - site fueling needs. However, their use is also regulated by safety and environmental standards to prevent accidents and pollution.

https://www.sumachine.com/

Recommended Products

Hot News

-

Double wall portable diesel gasoline cube tank with pump sale for Mauritius

2024-11-11

-

Double Walled Portable Fuel TransferCube Tank Ship To Spain

2024-11-07

-

Shipping of portable aviation fuel tank with pump

2024-10-12

-

Carbon steel diesel fuel cube tank ship to USA

2024-11-14

-

Carbon steel cube tank with pump

2024-11-13

-

Fuel Transfer Tank Cube Stationary Double Walled Diesel Storage Tank Sale For Spain

2024-11-06

-

251 US Gallon 552 Gallon Fuel Cube Transfer Tank Sale For USA

2024-11-05

-

251-2000 Gallon Fuel Cube Transfer Tank Sale For Grenada

2024-11-01

-

552 Gallon portable fuel dispenser with tank sale for USA

2024-10-30

-

Mobile fuel tank with pump sale for Spain

2024-10-22

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

IS

IS

KA

KA

HT

HT

KK

KK

UZ

UZ