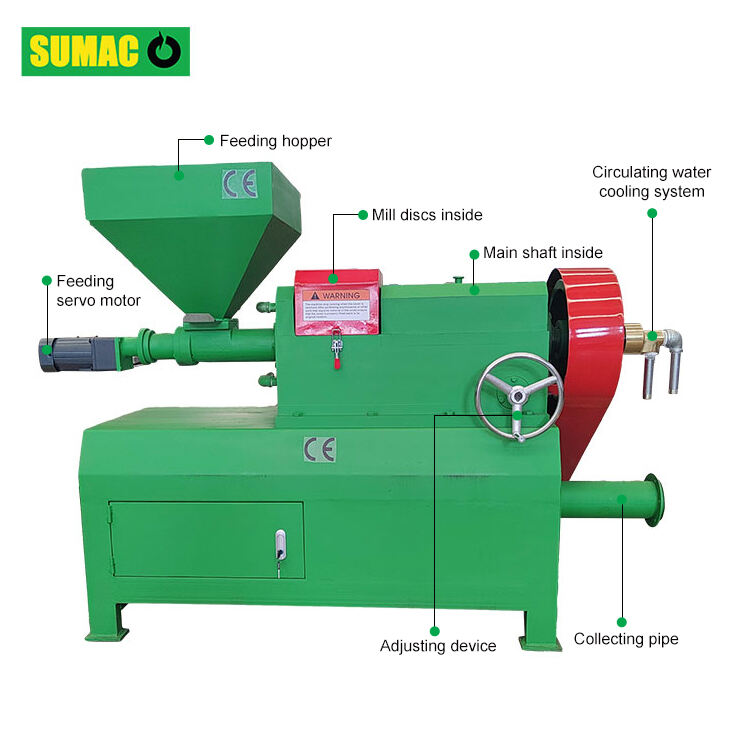

Model | CXFJ-28 | Capacity | 40~150kg/h |

Input size | 1-4mm | Power | 30.2Kw |

Output size | 30~100mesh | Cooler | Water cooling |

Weight | 1200Kg | Dimension(LxWxH) | 1920x1250x1320mm |

SUMAC

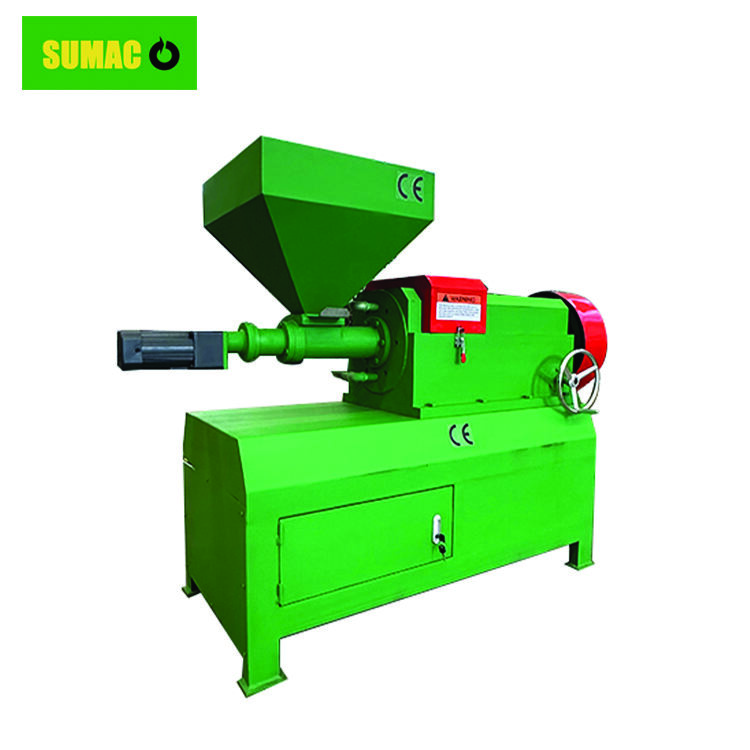

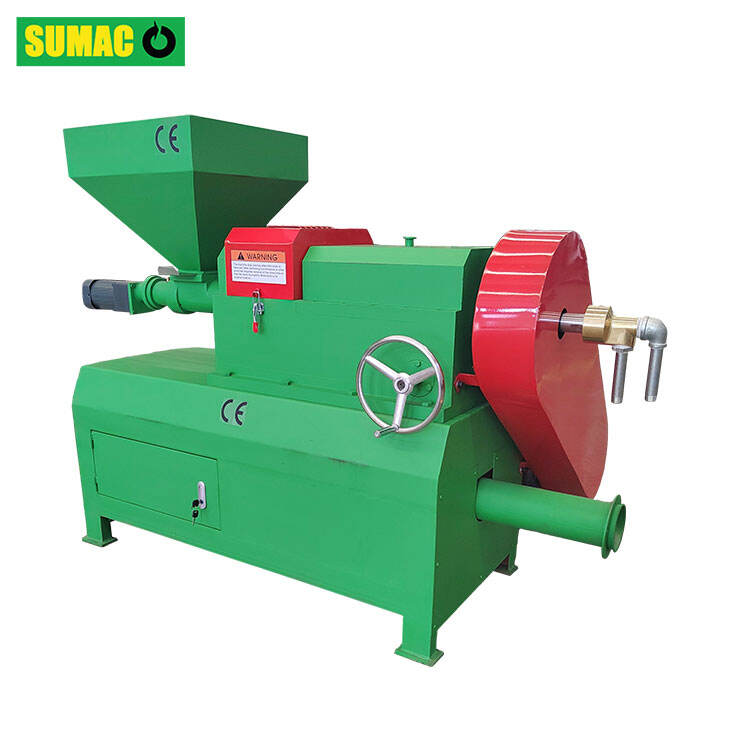

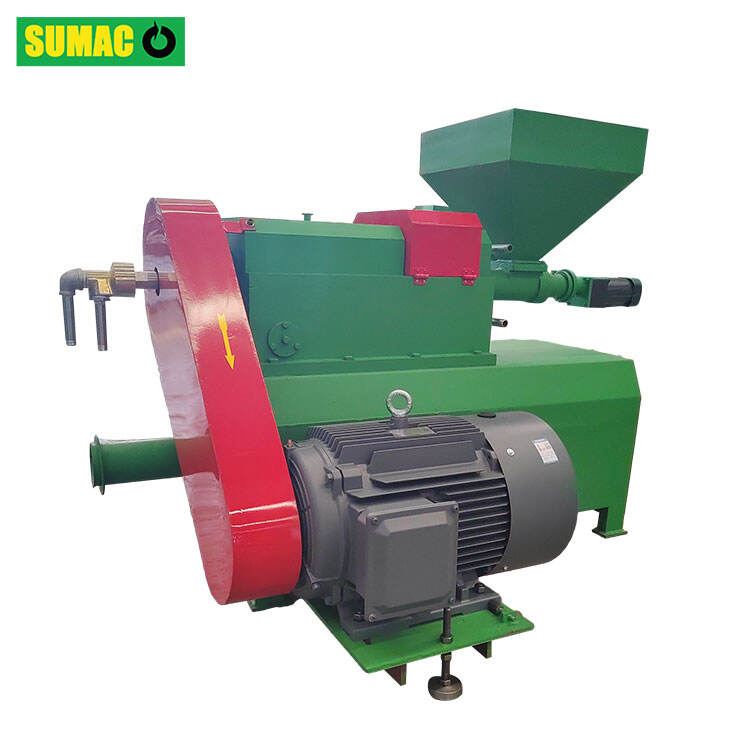

The rubber powder making machine is an innovative product designed to maximize the recycling of waste tires. This machine can be placed on the waste tire recycling production line, making the process more efficient and cost-effective.

The employment is an easy method is very good reduce waste and promote sustainability. Rather than getting rid of utilized tires, they could be transformed into valuable materials raw this machine. The SUMAC plastic powder made by this machine can be used for a range of applications, including the production of new tires, construction materials, along with other products rubber-based.

One of many benefits is its efficiency. Created to be highly automatic, which means so it requires minimal intervention is human operate efficiently. This saves time and reduces labor costs for waste tire recycling organizations. Highly customizable, meaning that it can be adjusted to match the precise needs of any organization.

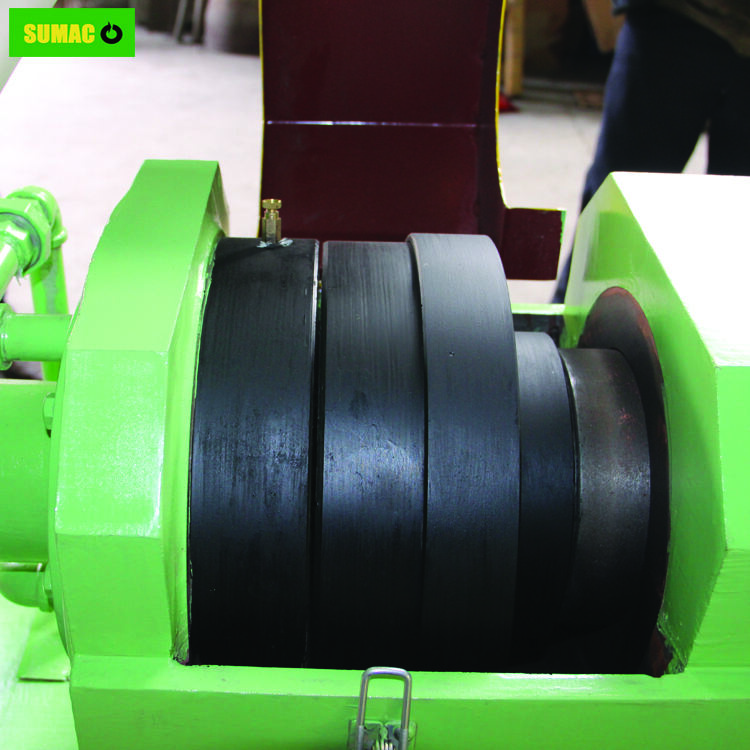

The SUMAC plastic powder machine is building a range of technologies to optimize the recycling process. As an example, a shredding can be used by it system to break straight down waste tires into smaller pieces, then processed into rubber powder. The equipment includes a dust collection system, which helps to ensure that the ongoing work place stays safe and clean.

Another advantage of the SUMAC rubber powder making machine is its durability. Made from high-quality materials, this machine is built to withstand the demands of continuous use. This helps to attenuate downtime and ensures that the machine continues to use efficiently for years in the future.

If you are looking for a reliable and effective way to recycle waste tires, the SUMAC rubber powder making machine is an excellent choice.

Our friendly team would love to hear from you!