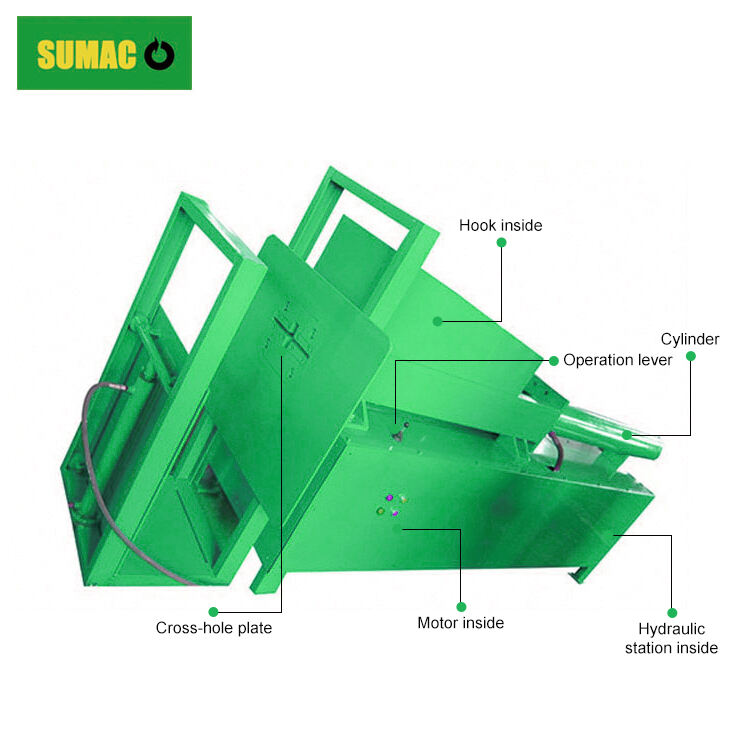

Model | LS-1200 |

Capacity(pcs/hour) | 20-40 |

Handling tire(mm) | ≤Φ1200 |

Motor power(Kw) | 11 |

Working pressure(Mpa) | 15 |

Pull(T) | 13 |

Weight(Kg) | 1400 |

Dimension(mm) | 3000*800*1000 |

SUMAC

Introducing Automatic Waste Tire Recycling Machine, the perfect solutions for effectively and efficiently recycling waste tires. This innovative machine is designed to streamlines the plastic and rubber shredding and recycling process.

Starts with the step is first of tires. The SUMAC equipment can effortlessly cut the plastic into smaller pieces, making them more straightforward to recycle using the utilization of the SUMAC Tire Debearded Rubber Cutting Equipment. Not only is this technique great for the surroundings, additionally it is economical, as it permits effortless recycling of waste that would end up in otherwise landfills.

Versatile in that it can recycle both used and brand-new engine motors. The SUMAC Automatic Waste Tire Recycling Machine is available in both brand new and models used to supply a solution is economical and environmentally sustainable.

One of the very most notable features of this recycling device is its efficiency. It can recycle large quantities of waste rubber and synthetic at a rate is fast reducing the time it takes to complete the recycling procedure. The machine uses technology is cutting-edge ensures consistent and precise outcomes, ensuring that the absolute most of plastic and plastic materials are recycled.

Additionally simple to operate, making it an option is great businesses of all sizes. The screen is user-friendly for ease-of-use, while the effective motor ensures a high level of precision and accuracy. This machine is designed to be maintenance is low with effortless access points for cleaning and maintenance.

Security is a concern is top the SUMAC Automatic Waste Tire Recycling Machine. The machine is equipped with safety features that prevent any possible accidents or accidents and adhere to safety is international.

The SUMAC Automatic Waste Tire Recycling Machine is a cost-effective and environmentally sustainable machines that can effectively and efficiently recycle waste tires. It can cut rubbers and plastic materials into smaller pieces, making them easy to recycle. Both new and used engines motors can be recycled, and the machines is easy to operate, low maintenance, and safe to use. It is an investment that can help businesses contribute to a cleaner and safer environment.

Our friendly team would love to hear from you!