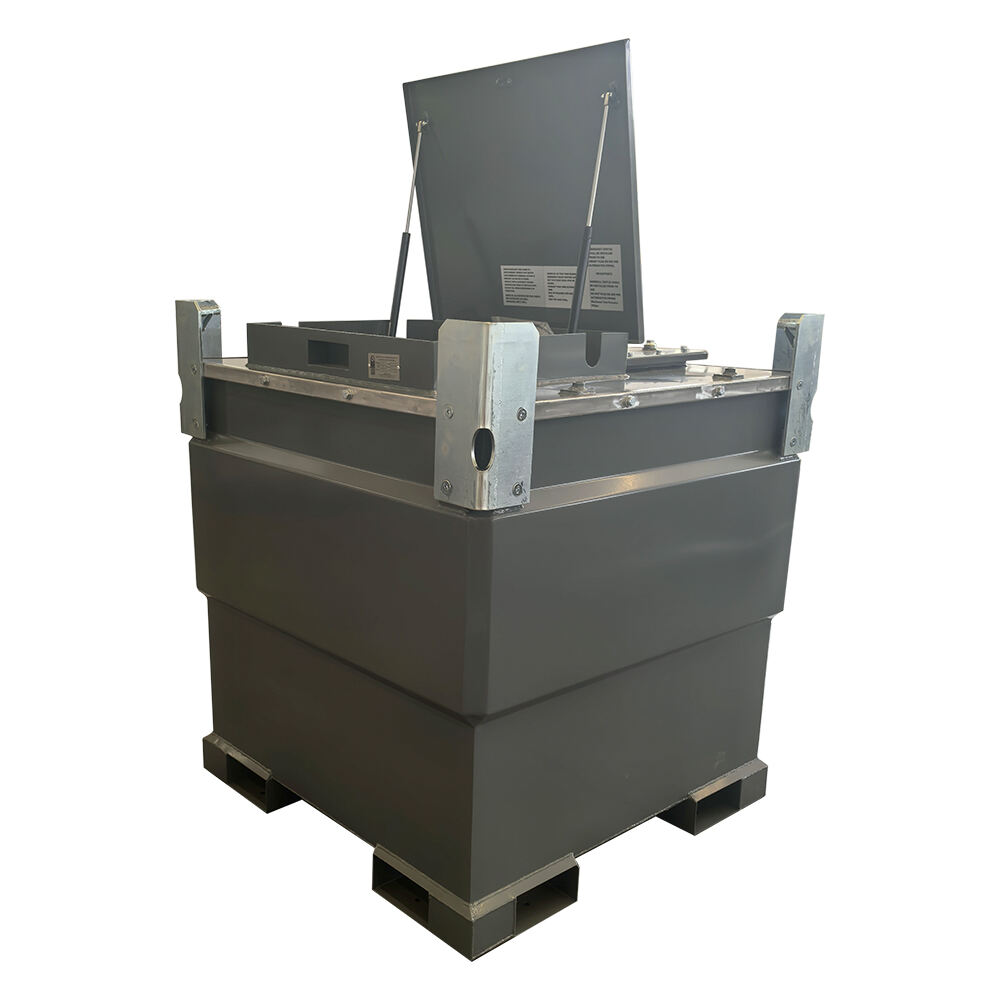

1000 Litre 2000l fuel cube tank sale for Spain

To effectively prevent oil tanks from leaking, we need to start from many aspects, such as tank material selection, manufacturing process, sealing treatment and daily maintenance.

1. Tank material selection

Use high-strength and corrosion-resistant steel to manufacture the tank. For example, stainless steel containing alloy elements such as chromium and nickel can effectively resist the erosion of chemical components in fuel and reduce the risk of tank perforation and leakage due to corrosion. Ensure that the quality of steel meets relevant standards and has good toughness and welding performance, laying the foundation for the stability of the overall structure of the tank.

2. Manufacturing process control

In the process of tank manufacturing, advanced welding technology is used. For example, gas shielded welding can reduce the mixing of impurities during welding and ensure that the weld is uniform and firm. Each weld must undergo strict non-destructive testing, such as ultrasonic testing, to accurately detect whether there are defects such as pores and cracks inside the weld. Once a problem is found, it should be repaired in time to prevent these defects from expanding and causing leakage in subsequent use.

3. Sealing treatment

For each interface of the tank, such as the oil inlet, oil outlet, manhole and other parts, install high-quality sealing gaskets. These gaskets must be made of oil-resistant rubber or other compatible materials, with good elasticity and aging resistance, to ensure that the interface fits tightly and prevent fuel leakage. Check the gasket status regularly, and replace it immediately if it is worn, hardened or deformed.

4. Daily maintenance and monitoring

Establish a daily inspection system, and the staff will regularly check the appearance of the tank to check for oil stains, deformation and other abnormalities. At the same time, install liquid level sensors and pressure monitoring devices to monitor the liquid level and pressure changes in the tank in real time. If the liquid level drops abnormally or the pressure fluctuates beyond the normal range, it may indicate a leak. The system will issue an alarm in time so that the staff can quickly check and repair it to minimize the risk of leakage.

https://www.sumachine.com/

Recommended Products

Hot News

-

Double wall portable diesel gasoline cube tank with pump sale for Mauritius

2024-11-11

-

Double Walled Portable Fuel TransferCube Tank Ship To Spain

2024-11-07

-

Shipping of portable aviation fuel tank with pump

2024-10-12

-

Carbon steel diesel fuel cube tank ship to USA

2024-11-14

-

Carbon steel cube tank with pump

2024-11-13

-

Fuel Transfer Tank Cube Stationary Double Walled Diesel Storage Tank Sale For Spain

2024-11-06

-

251 US Gallon 552 Gallon Fuel Cube Transfer Tank Sale For USA

2024-11-05

-

251-2000 Gallon Fuel Cube Transfer Tank Sale For Grenada

2024-11-01

-

552 Gallon portable fuel dispenser with tank sale for USA

2024-10-30

-

Mobile fuel tank with pump sale for Spain

2024-10-22

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

IS

IS

KA

KA

HT

HT

KK

KK

UZ

UZ