Carbon steel double walled portable diesel fuel cube tank with pump

Carbon Steel Double Wall Portable Diesel Fuel Tank with Pump

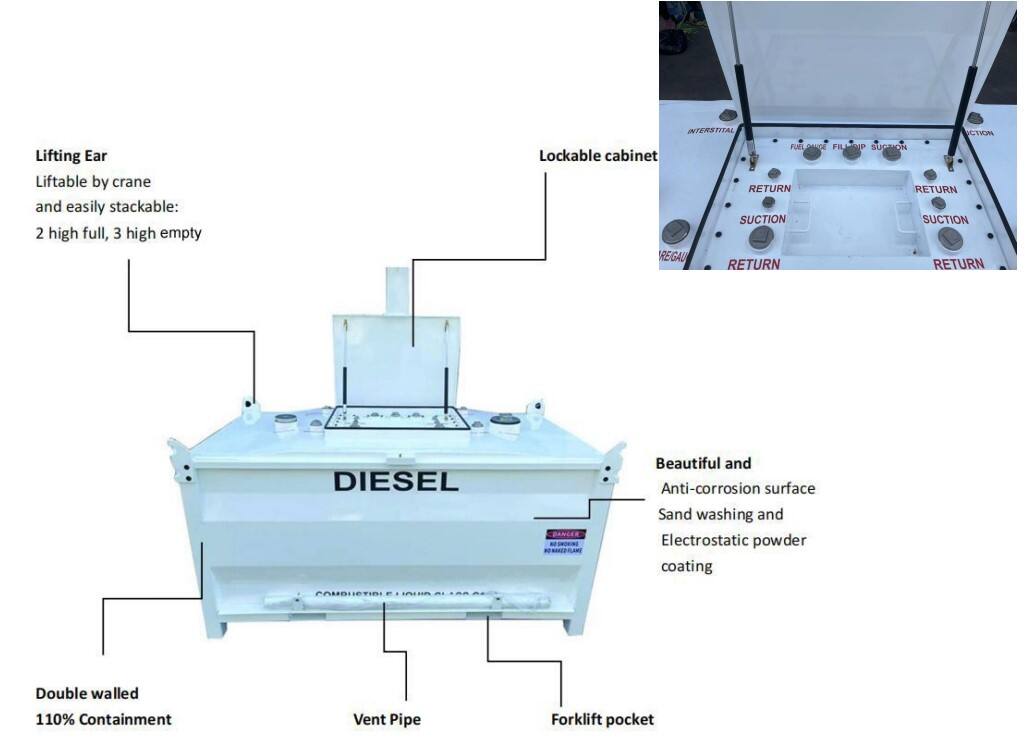

1. Carbon Steel Construction

Carbon steel is a common material used to make fuel tanks because of its strength and durability. It can withstand the weight of the fuel as well as external pressure and impact that may occur during transportation or storage.

The carbon steel used is usually treated to prevent corrosion. This may involve coatings such as paint or special anti-corrosion chemicals. For example, some tanks have a zinc-based primer followed by a topcoat to protect the steel from rust and chemical damage caused by diesel fuel.

2. Double Wall Design

The double-walled structure provides an extra layer of protection. The outer wall acts as a barrier to prevent the outside environment from causing physical damage to the structure. If the outer wall is punctured or damaged, the inner wall still contains the fuel, reducing the risk of leakage.

It also provides enhanced safety in case of a leak in the internal tank. The space between the two walls can be monitored for any signs of a fuel leak. For example, sensors can be installed in this gap space to detect the presence of fuel and trigger an alarm if a leak occurs.

3. Portable Design

These tanks are designed to be easily moved from one location to another. They often have features such as forklift pockets or lifting eyes. The cubic design provides stability during transport and storage.

Portable fuel tanks are useful in a variety of situations, such as construction sites where diesel is needed to power heavy machinery. They can be quickly relocated as the work area changes or refueling needs change.

4. Diesel Compatibility

Carbon steel is generally compatible with diesel fuel. However, it is important to ensure that the internal lining and seals of the tank are also suitable for diesel fuel. The tank should be designed to prevent fuel degradation due to contact with the wrong materials.

Some tanks have special fuel-resistant coatings on the inner walls to prevent any chemical reactions between the fuel and the tank materials that could cause fuel contamination or tank damage.

5. Pump

The pump attached to the tank is a critical component. It allows for efficient fuel transfer from the tank to the device being refueled. There are different types of pumps such as manual pumps and electric pumps.

Electric pumps are more convenient for larger volume refueling operations. They can provide a consistent flow rate and may have an automatic shut-off feature when the device's tank is filled. On the other hand, manual pumps are useful in situations where electricity is not available or for more precise dispensing of small amounts of fuel.

When using this type of tank, all safety regulations and guidelines regarding diesel storage and handling must be followed to prevent accidents and environmental damage.

https://www.sumachine.com/

Recommended Products

Hot News

-

Double wall portable diesel gasoline cube tank with pump sale for Mauritius

2024-11-11

-

Double Walled Portable Fuel TransferCube Tank Ship To Spain

2024-11-07

-

Shipping of portable aviation fuel tank with pump

2024-10-12

-

Carbon steel diesel fuel cube tank ship to USA

2024-11-14

-

Carbon steel cube tank with pump

2024-11-13

-

Fuel Transfer Tank Cube Stationary Double Walled Diesel Storage Tank Sale For Spain

2024-11-06

-

251 US Gallon 552 Gallon Fuel Cube Transfer Tank Sale For USA

2024-11-05

-

251-2000 Gallon Fuel Cube Transfer Tank Sale For Grenada

2024-11-01

-

552 Gallon portable fuel dispenser with tank sale for USA

2024-10-30

-

Mobile fuel tank with pump sale for Spain

2024-10-22

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

IS

IS

KA

KA

HT

HT

KK

KK

UZ

UZ